Outside of the logistics business, many may not see its significance. Still, security seals are known widely as tamper-evident mechanisms used to secure in-transit shipments. High-Security Seals is one of the three major security seals categories and offers the most excellent protection level. However, ISO accreditation is required for a security seal to be categorised as “High-Security Seal”. How much do you know about ISO and High-Security Seals?

What is ISO 17712?

ISO (International Organization for Standardization) is the world’s largest developer of voluntary International Standards. It is a set of requirements, specifications, guidelines to ensure that materials, products and services are safe, reliable, and of good quality.

ISO 17712 is the standardised document that establishes “uniform procedures for the classification, acceptance, and withdrawal of mechanical freight container seals. It provides a single source of information on mechanical seals which are acceptable for securing freight containers in international commerce.” it defines three types of classes of security seal strength, or tensile strength: “I” for Indicative; “S” for Security; and “H” for High Security.

The ISO 17712 standard requires independent testing against three main categories:

- Mechanical Testing to determine a security seal’s physical strength (Clause 5).

When undergoing mechanical testing by an ISO 17025 accredited independent laboratory (Clause 5), the manufacturer must be certified to ISO 9001 and ISO 17712: Annex A. The ISO 17712:2013 states that the complying security seals must be categorized and marked “H” as High-Security Seals. - Seals are designed and constructed with tamper indicative features that generate tell-tale evidence of tampering (Clause 6).

The ISO 17712:2013 also states that the security seal must also be compliant with Clause 6: Evidence of Tampering. This requires a documented and audited process and test specification in its quality manual for all High-Security Seals. Clause 6 emphasises the importance of continuous improvement of tamper-resistant and tamper-indicating features on security seals. - Auditing of manufacturer’s security-related business processes (Annex A).

To ensure a high-quality security seal’s effectiveness, ISO 17712:Annex A defines requirements such as facility risk assessments and access controls to production and storage areas. Suppliers’ conformance with Annex A should also be demonstrated through compliance auditing by an ISO accredited independent certification provider.

Who are the ISO alliances?

- CTPAT

The Customs Trade Partnership Against Terrorism (CTPAT) voluntary alliance program was a result of 9/11. It is one of the U.S. Customs and Border Protection’s multi-layered strategies for securing cargo inbound to and outbound from the United States. ISO-compliant High-Security Seals are among the security requirements for partnership shippers, applying on containers and trailers. CTPAT members are considered low risk and are therefore less likely to be examined at a U.S. port of entry. Through CTPAT, the U.S. government can identify and correct vulnerabilities within the global supply chain and strengthen international supply chains with a collective effort from manufacturers and shipping companies. - World Customs Organization (WCO) SAFE Framework

The World Customs Organization (WCO) is an independent intergovernmental organisation to enhance Customs administrations’ effectiveness and efficiency. Today, WCO represents 183 Customs administrations worldwide, including developing countries that partake about 90% of the world trade. SAFE Framework is a commitment by member countries to implement trade security programs. That is similar to CTPAT, which provides benefits to businesses that meet SAFE-defined standards and best practices. ISO-compliant High-Security Seals is part of its first pillar to secure containers from customs to customs in all sites and terminals. - European Union Authorized Economic Operator (EU AEO)

The European Union’s Authorized Economic Operator programme (AEO) is comparable to the US Customs Trade Partnership Against Terrorism (CTPAT) program. The AEO program is focused on upgrading supply chain security while contributing to trade facilitation and reforming and modernizing customs around the world. ISO compliant High-Security Seals is part of its guidelines. Proper documentation of the seals’ usage is required to ensure cargo integrity and prevent irregular practices in the international supply chain flow. - Canadian Partners in Protection (PIP)

Partners in Protection (PIP), the supply chain security program of the Canada Border Services Agency, was initially established in 1995 as a program focused on customs’ compliance. The Canada Border Services Agency (CBSA) and the United States Customs and Border Protection (U.S. CBP) have committed to harmonizing the PIP and CTPAT programs, focusing on highway carriers. It has since transformed to actively deal with supply chain security as its main objective.

Generally, security seals are required to be applied on all doors and latches as the inspection proceeds.

Who needs ISO-certified High-Security Seals?

These regulations above are the most essential standards to be familiar with to ensure cargo is safe and secure when transported across the world.

- Manufacturer/Importer: The manufacturer or importer supplies seals to its foreign suppliers and/or foreign consolidators.

- Ocean Container Line: The ocean container line provides one seal with every empty container. It is the responsibility of the importer to confirm that high-security seals are utilized.

- Foreign Supplier: The foreign supplier picks the consolidator and/or ocean container line. It is the responsibility of the importer to confirm with the foreign supplier how seals are obtained. The importer should require that the foreign supplier provide written documentation on how the seals are obtained, along with seal specifications and/or a sample seal.

- Foreign Consolidator: The foreign consolidator picks the ocean container line. It is the responsibility of the importer to confirm with a provided written documentation as to how the seals are obtained, along with seal specifications and/or a sample seal.

- Freight-forwarder: The freight-forwarder picks the consolidator and/or ocean container line.

Mega Fortris High-Security Seals

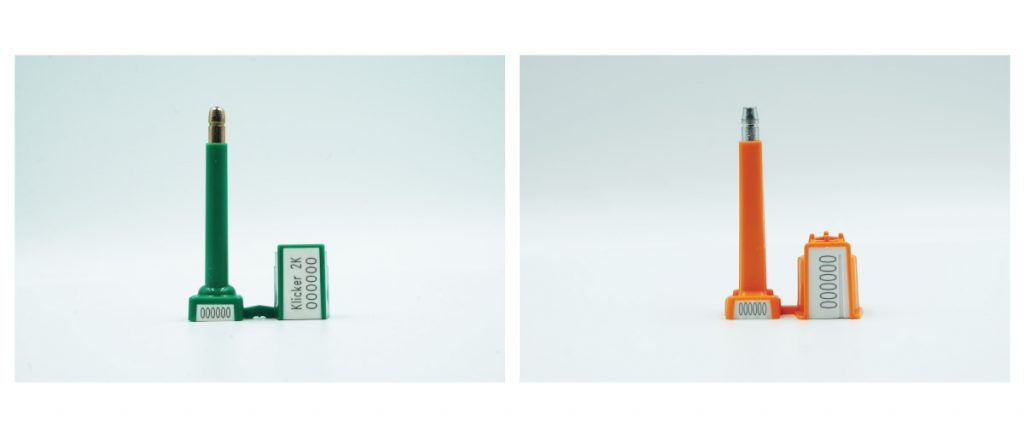

High-Security Seals, as the entry barriers, are generally made of metal and to indicate tampering. High-Security Seals by Mega Fortris are CTPAT and ISO 17712 compliant. Our High-Security Seals range consists of container bolt seals and cable barrier seals. Those are ideal for cross-border cargo protection, hence ensuring reliable usage for shipments and audits.

To further enhance the tamper evidence and embrace the technology advancement, two-coloured body container bolt seals are designed to indicate tampering on the identifiers, as well as for ease of operation. Barcodes and QR codes are among the high-demand laser marking identifiers as industry players integrate Internet-of-Things in their operation. Two-coloured body High-Security Seals in Mega Fortris are Klicker 2K and Fort Container Seal.

Our High-Security Seals are globally recognised for their high quality and ISO 17712 compliance. To learn more about the wide range of security seals available for different cargo and modes of transport, visit Mega Fortris website, a trusted, world-class security seal designer and manufacturer with over 20 years of experience.